What is the FOB price of Cement Products?

Introduction

Cement is a very useful binding material in construction. The applications of cement over various fields of construction have made it a very important civil engineering material.

It is used in the construction of important engineering structures such as bridges, culverts, dams, tunnels, lighthouses etc.

Cement is mainly used as a binder in concrete, which is a basic material for all types of construction, including housing, roads, schools, hospitals, dams and ports, as well as for decorative applications (for patios, floors, staircases, driveways, pool decks) and items like tables, sculptures or bookcases.

Although the terms cement and concrete often are used interchangeably, cement is actually an ingredient of concrete. Concrete is a mixture of aggregates and paste. The aggregates are sand and gravel or crushed stone; the paste is water and Portland cement.

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

The most common way to manufacture Portland cement is through a dry method. The first step is to quarry the principal raw materials, mainly limestone, clay, and other materials. After quarrying the rock is crushed. This involves several stages. The first crushing reduces the rock to a maximum size of about 6 inches. The rock then goes to secondary crushers or hammer mills for reduction to about 3 inches or smaller.

The crushed rock is combined with other ingredients such as iron ore or fly ash and ground, mixed, and fed to a cement kiln.

The cement kiln heats all the ingredients to about 2,700 degrees Fahrenheit in huge cylindrical steel rotary kilns lined with special firebrick. Kilns are frequently as much as 12 feet in diameter—large enough to accommodate an automobile and longer in many instances than the height of a 40-story building. The large kilns are mounted with the axis inclined slightly from the horizontal.

The finely ground raw material or the slurry is fed into the higher end. At the lower end is a roaring blast of flame, produced by precisely controlled burning of powdered coal, oil, alternative fuels, or gas under forced draft.

As the material moves through the kiln, certain elements are driven off in the form of gases. The remaining elements unite to form a new substance called clinker. Clinker comes out of the kiln as grey balls, about the size of marbles.

Clinker is discharged red-hot from the lower end of the kiln and generally is brought down to handling temperature in various types of coolers. The heated air from the coolers is returned to the kilns, a process that saves fuel and increases burning efficiency.

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to ready-mix concrete companies to be used in a variety of construction projects.

Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process. The two processes are essentially alike except in the wet process, the raw materials are ground with water before being fed into the kiln.

CLINKER

Cement Clinker

Clinker is a nodular material produced in the kilning stage during the production of cement and is used as the binder in many cement products. The lumps or nodules of clinker are usually of diameter 3-25 mm and dark grey in color.

Grey Cement

Grey Portland Cement

Grey cement (or Ordinary Portland Cement) is one of the most important elements used in construction. Its raw materials contain high amounts of iron oxide and manganese oxide. Its particles are less fine than those of white cement.Its particles are finer than those of grey cement.

White Cement

White Portland Cement

White Portland cement or white ordinary Portland cement (WOPC) is similar to ordinary, gray Portland cement in all aspects except for its high degree of whiteness. Obtaining this color requires substantial modification to the method of manufacture, and because of this, it is somewhat more expensive than the gray product.

White Portland cement is used in combination with white aggregates to produce white concrete for prestige construction projects and decorative work. White concrete usually takes the form of pre-cast cladding panels, since it is not economical to use white cement for structural purposes. White Portland cement is also used in combination with inorganic pigments to produce brightly colored concretes and mortars.

Gypsum

Gypsum rock

Gypsum is a soft sulfate mineral composed of calcium sulfate dihydrate, with the chemical formula CaSO4·2H2O. It is widely mined and is used as a fertilizer and as the main constituent in many forms of plaster, blackboard/sidewalk chalk, and drywall.

As a rock, gypsum is a sedimentary rock, typically found in thick beds or layers. It forms in lagoons where ocean waters high in calcium and sulfate content can slowly evaporate and be regularly replenished with new sources of water. The result is the accumulation of large beds of sedimentary gypsum.

Gypsum is used include: manufacture of wallboard, cement, plaster of Paris, soil conditioning, a hardening retarder in Portland cement.

FOB Prices for Clinker, Grey Cement, and White Cement/ per MT

Cement Clinker

$18

Portland Cement Clinker-Type II

Status: Fresh, and High-Quality

Standard: ASTM C-150

Delivery: FOB-BIK Port

Payment Terms: TT

Grey Cement

$34

Grey Cement-Type II

Status: Fresh, and High-Quality

Standard: ASTM C 150- Type II

Delivery: FOB-BIK Port

Payment Terms: TT

White Cement

$59

Portland White Cement-52,5

Status: Fresh, and High-Quality

Standard: EN 197-1, 52,5

Delivery: FOB-BND Port

Payment Terms: TT

Gypsum

Rock

$8

GYPSUM rock

Status: High-Quality

Standard: Purity 90-95%

Delivery: FOB-BND Port

Payment Terms: TT

CIF offer

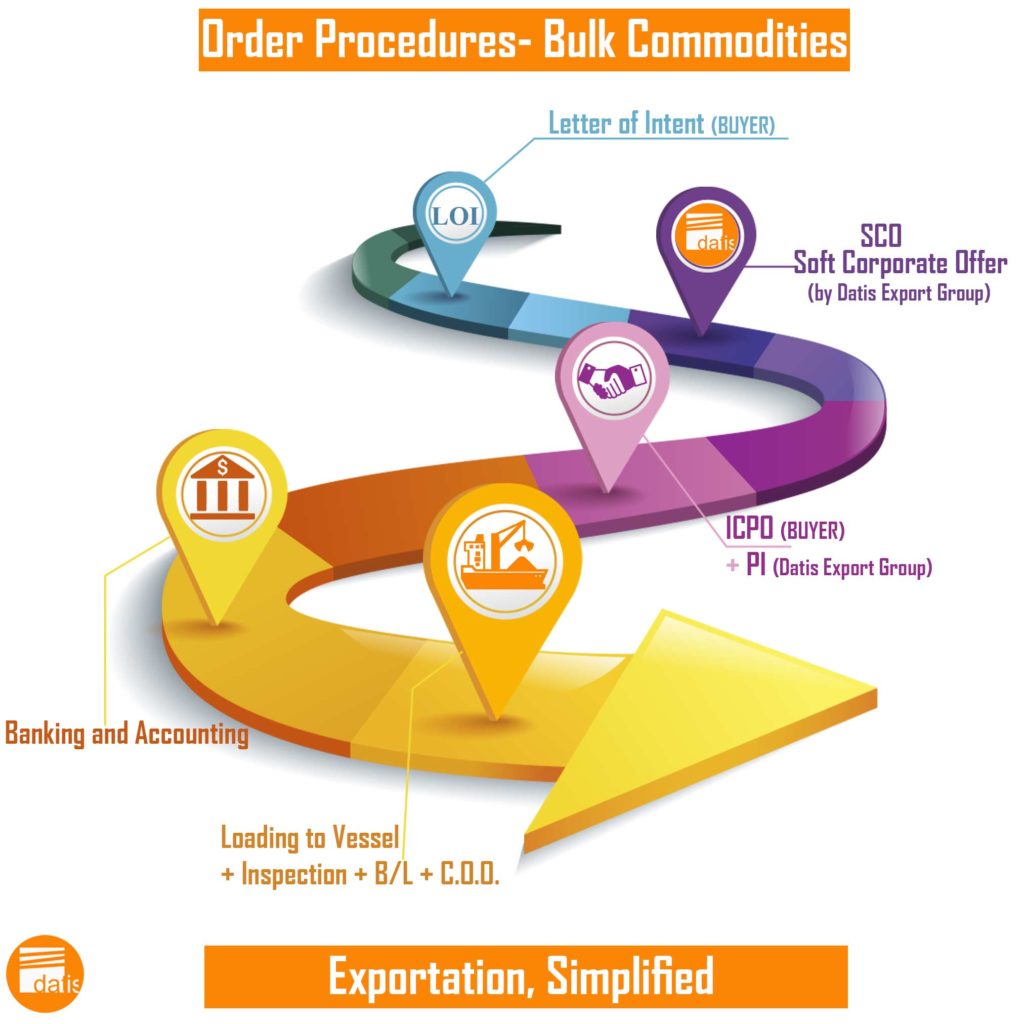

Letter of Intent-LOI in the first level

For CIF offer, our sales team should determine all details such as the product cost, transit to the port of loading, loading to the vessel (or stuffing), customs duties, etc.

we require to obtain accurate information on the inquiry as Letter of Intent-LOI in the first level. Please mail us LOI to our Sales Team.