Clinker Calcination

All things about cement clinker calcination in the cement production process

Cement Clinker Production

The cement industry is an indispensable basic raw material industry for national economic development, production construction, and people’s livelihood. It is widely used in civil construction, water conservancy, national defense, and other fields. The development scale of a country’s cement industry reflects its level of economic and urban development to a certain extent. Since the 21st century, with the continuous growth of the global economy, the cement industry has undergone a breakthrough change.

Intensive production of new equipment has gradually replaced the backward mode, and industrial technology has developed rapidly. Up to now, there are nearly 700 cement enterprises and countless cement plants of various sizes are engaged in the manufacturing of cement equipment and cement in the world.

Cement production is a complex process. A batch of high-quality cement needs many kinds of raw materials to be mixed together and then formed through layers of working procedures. Problems occurred at any stage will affect the quality of the final products.

Clinker calcination is the core part of the cement manufacturing, in which raw materials react with each other at high temperatures and eventually form clinkers. So next, we will have a detailed understanding of the clinker calcination and cement production process.

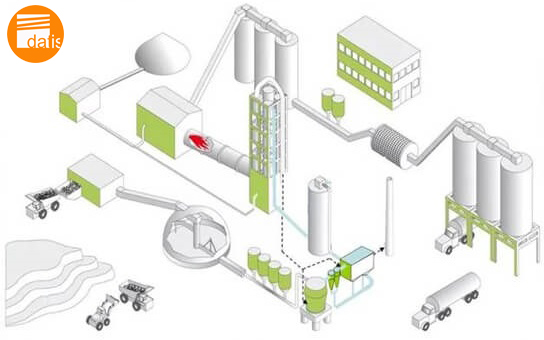

Cement Production Process

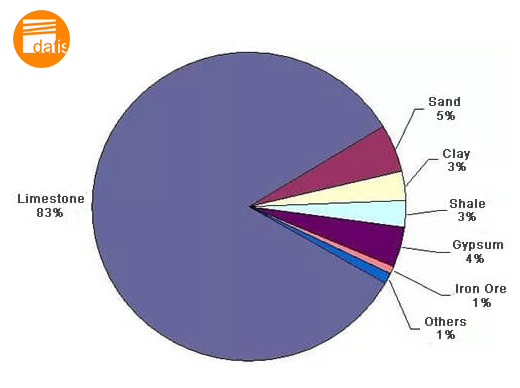

The cement production processes mainly include raw material crushing and storage, raw material proportioning and grinding, clinker calcination, clinker grinding, cement packing, etc. Portland cement is the most widely used cement in our daily life. It is made from a variety of raw materials, typically sand, iron ore, clay, gypsum, limestone, shale, etc. Limestone is the main one, accounting for 83% of the raw materials.

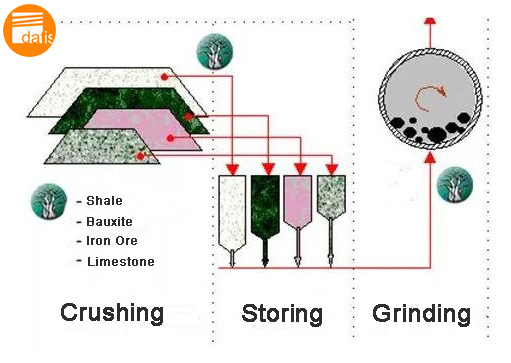

Raw material crushing and storage

is the first step of cement production. In this step, raw materials should be fed into the crushing mill to reach an appropriate granularity, and then be homogenously stored in the steel silo for further processing.

Raw material proportioning and grinding

is the second step, in which the manufacturer will prepare the raw mix according to the requirements of clinker ingredients. Generally, limestone will take up a large proportion, as to other corrective materials such as sand and iron ore are added in small amounts to ensure that the chemical composition of the raw mix satisfies the process and product requirements.

After that, the raw mix will be sent into the ball mill or other grinders so that the particle size of the powder reaches a certain degree of fineness. The higher the grinding fineness is, the faster the reaction speed in the rotary kiln.

Clinker calcination

is the most crucial part of the whole process of cement manufacturing. At this stage, ground raw materials will be sent into the cement kiln and be heated at a high temperature to produce chemical reactions with each other, eventually forming clinker. In addition, clinkers that just complete the calcination will have a high temperature, thus a cooling machine is usually placed behind the rotary kiln so that the clinker can go directly into the cooler for dropping to normal temperature.

Clinker Grinding

is the final step in cement production. The cooled clinker is a kind of granular material with different particle sizes. They will be ground in the grinding mill to reach the qualified fineness of cement products. During the grinding, 2-3% gypsum powder is added as retarder so that when cement contacts with water, its solidification speed will not be too fast.

Sometimes, we also add some other minerals (blast furnace slag, fly ash, etc.) to obtain the desired cement performance. After all the above processes are completed, the cement will be packaged and sent to its destination.

Clinker Calcination Process

The cement manufacturing processes can be totally classified into dry method process and wet method process. The main difference between them lies in the different mix and preparation method of raw material. In the wet process, water is usually added to the raw mix to form the slurry. While in the dry process, the raw mix is the fine powders after grinding and drying. The selection of process is mainly based on the nature of raw materials. When their moisture content is more than 20%, the wet process will be preferred.

In the past, the wet process was mostly used in cement production because it was easier to control the chemical composition of the raw mix, the chemical composition is distributed more evenly and the clinker had better quality, but it consumes more energy. At present, most cement plants adopt the dry method process.

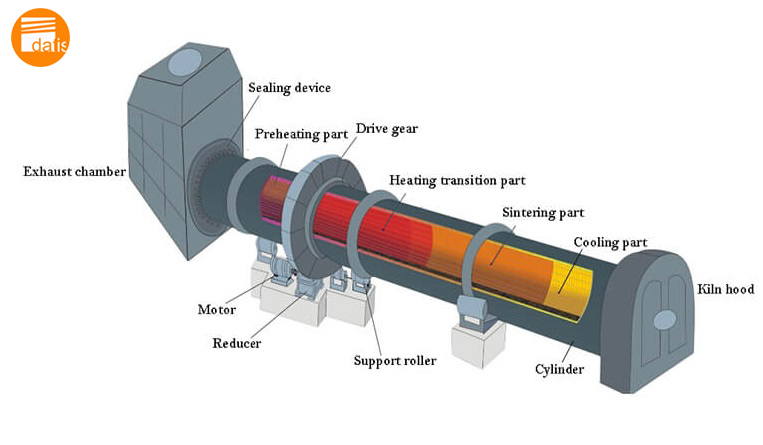

Rotary kiln is the equipment where clinker calcination takes place. According to different processes, it can be divided into dry method cement kiln and wet method cement kiln.

Dry method cement kiln

In general, the moisture content of materials in the dry method cement kiln is less than 1%, so this kind of kiln can reduce the heat needed for evaporating water. But this method also has its drawbacks, that is, the fluidity of materials in the cement kiln is poor, resulting in uneven clinker composition.

Wet method cement kiln

The wet method of cement kiln mainly processes raw material slurry with the water content of 32%-40%. The main advantage of this kiln is the good fluidity of raw mix slurry. However, the heat required for evaporating water in this kiln consumes a lot of energy, which is not conducive to energy saving and environmental protection.

Complete Clinker Calcination System

In actual calcination, a complete clinker calcination system includes the cooler, pulverized coal combustion equipment, blower, exhaust fan, and the dust collector. However, in the latest calcination system, the addition of preheater and precalciner reduces the energy consumption and optimize the performance of cement kiln to a large extent.

The raw mix in the preheater is preheated and partially calcinated 30% before entering the rotary kiln. In addition, the application of pre calciner significantly increases the clinker capacity of the cement kiln. After that, the raw mix will enter the rotary kiln for further calcination.

Clinker production stages

When raw meals enter the rotary kiln and are heated by the high temperature, they will go through six reaction stages in turn, namely drying, preheating, chemical decomposition, exothermic reaction, sintering and cooling. The operations of each stage are as follows:

- Drying: the raw mix will firstly complete the water evaporation after entering the rotary kiln. At this time the temperature of the material is between 20-200 ℃.

- Preheating: when the raw mix’s temperature rises to 450 ℃, the clay will dehydrate (remove the chemically bound water) and become amorphous oxide. At this time, the temperature in cement kiln is 200-750 ℃.

- Chemical decomposition: at this stage, the material changes dramatically and lasts for a long time. At the same time, a large amount of carbon dioxide is produced. Because of the large amount of gas in the kiln, the material flow speed becomes fast. The temperature in cement kiln is up to 750-1000 ℃.

- Exothermic reaction: it is a solid phase change of materials. The temperature difference between this stage and the decomposition stage is large, so the material has a strong luminescence. The temperature of this stage is 1000-13000 ℃.

- Sintering: it is also known as lime absorption. The tricalcium silicate is produced at this stage and the temperature in cement kiln is up to 1300-1450℃.

- Cooling: at the cooling step, materials are cool down in rapid time. Its main purpose is to prevent the decomposition of tricalcium silicate. The temperature of cement kiln is between1300-1000 ℃.

Now if you are looking for a high-quality standard CLINKER, you may look at our offered Clinker in this link: